Litlhaloso

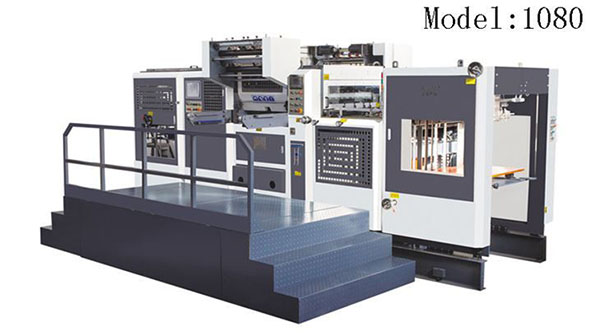

| Mohlala | XLTYM-1080 |

| Max.Boholo ba Pampiri(mm) | 1080×780mm |

| Min.Boholo ba Pampiri(mm) | 400 × 370 limilimithara |

| Max.Boholo ba ho seha: (mm) | 1070×770mm |

| Max.Boholo ba Setempe sa Foil: (mm) | 1020*710mm |

| Max.Lebelo la ho Sebetsa | 7000s/h |

| Max.Lebelo la Setempe | 5500s/h |

| Khatello e Phahameng | 300T |

| Stamping Setting Temperature | 0-199 ℃ |

| Max Foil Diameter | Φ100mm/1"Φ195mm/3" |

| Max.Bolelele ba foil ba longitudinal | 710 limilimithara |

| Max.Bolelele ba foil ba ka morao | 1020 limilimithara |

| Ho futhumatsa boleng | 12 |

| Longitudinal foil shaft | 3QTY |

| Lateral foil shaft | 2QTY |

| Min.Bolelele ba foil | 0.01 limilimithara |

| Botenya ba Leqephe | E entsoe ka makotikoti≤4mm |

| 0.1mm≤Paperboard≤1.5mm | |

| Matla a poleiti ea ho futhumatsa | 24KW |

| Matla a motlakase a ka sehloohong | 15KW |

| Kakaretso ea matla | 56KW |

| Boima bo felletseng | 18T |

| Kakaretso ea litekanyo(mm) | 6000 * 4000 * 2300mm (eseng ho kenyelletsa karolo ea ho kenya pele) |

Lesiba le ka sehloohong

Mochini oa Automatic Foil Stamping & Die-cutting o na le sesebelisoa sa ho hatakela se otlolohileng le se otlolohileng, sebopeho se na le kahlolo e molemo, ts'ebetso e bonolo, e sebelisoa haholo bakeng sa ho seha, ho qhekella, ho hatakela ka foil, ho qoelisoa ha sakerete ho bata le ho chesa. lebokose, lebokose la lithethefatsi le leibole liindastering tsa ho paka le ho khabisa.Mochini o amohela theknoloji e phahameng ea ho hlokomela ho fepa ka boiketsetso, ho itšeha, ho hatakela, ho fana, ho hatisa, ho hatella, ho tlola, ho bala, ho futhumatsa, ho futhumatsa pele, tšitiso e bonts'ang, ho lekola le ho lekanya.Ka masiba a ts'ebetso e bonolo, ho tšepahala, lebelo le phahameng, khatello le ho nepahala.

E netefalitsoe ke sistimi ea boleng ea ISO9001 mme e kopana le maemo a polokeho a CE.

Likaroloana

I. Karolo ea ho Fepa Lipampiri

1. Mochine ona o nka mochine o boima oa lebelo le phahameng o ikamahanyang le phallo e phahameng le e tsitsitseng ea mefuta eohle ea pampiri.

2. Mochini oohle o phahamisitsoe mme o hlomelloa ka sesebelisoa sa pampiri sa pele ho khouto.

3. Ho sebelisa mokhoa oa ho fana ka pampiri ea sekala sa tlhapi.Tšebeliso ea ho foka ka mahlakoreng ho etsa hore pampiri e be boreleli haholoanyane.

4. Hlooho ea phepelo le qubu ea pampiri e ntlafalitsoe ho etsa hore ts'ebetso e be bonolo haholoanyane, e be bonolo le ho ntlafatsa ho nepahala ha boemo ba qubu ea pampiri.

5. Enjene ea lisebelisoa tsa boleng bo holimo tsa Taiwan, lerata le tlase, torque e phahameng, ho netefatsa qubu e boreleli ea metsamao ea pampiri.

II.Foil Stamping

1.Likarolo tse ka sehloohong tsa mochine o ka sehloohong (ho kenyeletsoa setsi, sethala, tafole e tsamaeang le lebota) li entsoe ka boleng bo phahameng ba lehlabathe la ductile iron casting, ho ntlafatsa haholo matla a mochine le ho netefatsa bophelo ba tšebeletso ea mochine;Meno a bulehileng le mekhatlo e meng e amohela sebopeho sa pampiri sa Switzerland BOBST, e le hore ts'ebetso e boreleli ea mochine o ts'epahale, ho nepahala le botsitso.

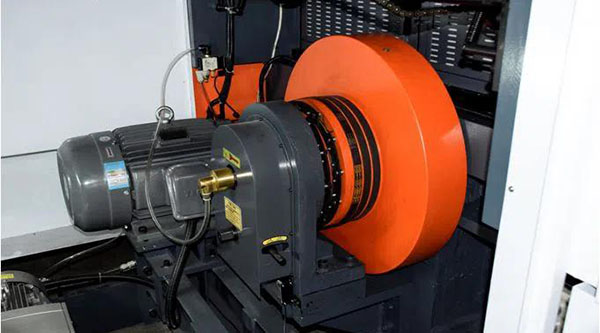

2.Italy e rekisitse clutch ea pneumatic, e seng feela e nang le melemo ea boholo bo bonyenyane, mocheso o motle oa mocheso, nako e khutšoanyane ea karabo, le tlhokomelo e bonolo le e ncha, e loketseng tšebeliso ea maqhubu a phahameng.

3.Lefapha la ho itšeha le ile la etsa moralo o utloahalang oa mochine o hatelitsoeng oa setsoe oa bar, ka nako e ts'oanang ka ts'ebetso e rarahaneng le ts'ebetso ea kopano, ho nepahala ha mochine ho fihlile boemong bo phahameng.Shoa ho itšeha khatello ea lithane tse 300 tsa mochini o moholo ka ho fetisisa, ho fihlela litlhoko tsa ts'ebetso ea bronzing.

4.Mochini o ikemetseng oa ho fetola khatello o laoloang ke frequency converter, ha o ntse o ntlafatsa ts'ebetso, o etsa hore tokiso ea khatello e be bonolo haholoanyane, e boreleli, e nepahale ebile e potlake.

5.Automatic taolo ya silindara die seha thipa phetolelo ea notlela, e le hore opereishene e be bonolo le e ka tšeptjoang.

6.Tenyetseha le e ka tšeptjoang piracy sesebediswa le bohareng ba foreime locator, e le hore poleiti hlomamisa ka potlako le ka nepo.

7.Moralo o ntlafalitsoeng oa ketane ea litsi tse sebelisang 'mele oa aluminium o thata oa boleng bo holimo le ketane ea kantle ho naha, e fokotsa haholo inertia e sebetsang, e ikamahanyang le tlhahiso e phahameng haholo.

8.Tšebeliso ea 230 ° ka mokhoa o nepahetseng oa nakoana, hammoho le mochine o ka etsa bonnete ba hore mochine o sebetsa hantle ka nako e le 'ngoe sethaleng, leino la leino le tšireletso e sebetsang ea' mele.

9.Khetho ea tšepe ea boima bo phahameng, thepa e phahameng ea elasticity, flatness e ntle, nako e telele;sesebediswa sa yona sa ho beha sebaka ka katleho se netefatsa boemo bo nepahetseng.

10.Lefapha la Host lubrication ea pula, e nang le sesebelisoa sa ho futhumatsa oli, se loketseng basebelisi ba libaka tse fapaneng.Karolo ea phetisetso ea mochini e na le sesebelisoa sa othomathike sa lubrication, se lelefatsang bophelo ba mochini haholo.

11.Libaka tse futhumatsang tsa sebaka sa 12, nako ea ho futhumatsa terata e nyane, taolo e nepahetseng ea mocheso, junifomo.Mocheso o mong le o mong oa libaka o ka laoloa ka bonngoe!

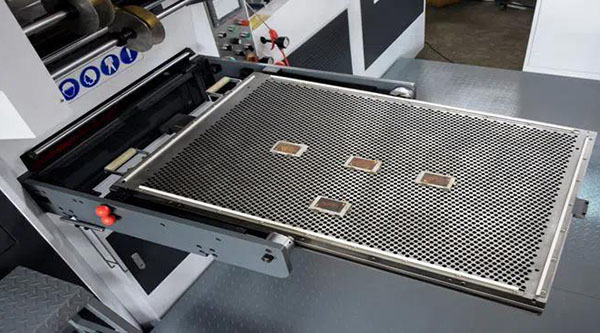

12.Phahameng matla a mahe a linotsi phanele ha ho bonolo ho deformation, phahameng flatness.Terene e thibelang mocheso ho etsa bonnete ba hore foil ha e holofetse, e nepahetse ebile e tsitsitse.

13.Rack ea foil e ka huleloa kantle ho mochini, ho nkela foil ea aluminium ho bonolo, ho boloka nako.

14.Aluminium foil stripping blowing control valve e ka fetoloa ho foka molumo oa moea, ho qoba foil e kholo ea setempe e chesang pampiring.

III.Delivery Karolo

1.ho sebelisa lebokose la li-gearbox tsa boleng bo holimo tsa Taiwan, lerata le tlase, torque e kholo, ho netefatsa hore qubu ea qubu ea pampiri e tsitsitse.'Me ka koloi ha e koale terata ho ntlafatsa haholo katleho ea tlhahiso.

2.Moralo o ntlafalitsoeng oa sesebelisoa sa brake brake o ka fihlela phetoho e sa emeng, e le hore pokello ea pampiri e tsitse le ho hloeka.

3.Lisebelisoa tse ntseng li eketseha tsa ho butsoa ha pampiri le lisebelisoa tse ka morao li ikamahanya le pokello ea lipampiri tse fapaneng.

4.Sebopeho sa sampole sa pneumatic se bonts'a moralo o nang le botho haholoanyane, etsa hore ts'ebetso e be bonolo le ho feta kapele.

IV.Karolo ea Taolo ea Motlakase

1.Karolo ea motlakase ea mochini e entsoe ho latela maemo a CE.Mefuta eohle ea ts'ireletso e lekoa ka switch.

2.Lebokose la motlakase le nang le moea le sehatsetsing, le lelefatsang bophelo ba likarolo tsa motlakase haholo.

3.Mochine o sebelisa theknoloji e phahameng, ho finyella ho tloha pampiring, ho khaola ho fihlela ho fana ka mochine oa pampiri.

4.Adopt encoder, kh'amera ea elektroniki e entsoeng ka taolo e hlophisehileng e ka tšeptjoa haholoanyane ebile ho bonolo ho e lokisa;inverter e sebelisoa ho laola enjene ea mantlha, taolo ea lebelo le se nang mohato le ts'ebetso e tsitsitseng.

5.Ho ea ka melao-motheo ea ergonomic, e nang le boto ea likonopo tse ngata tsa ts'ebetso, joalo ka pampiri ho ea setšeng, sebaka sa phetisetso, sebaka sa ho sebetsa le sebaka sa ho fana ka thepa, ho finyella likarolo tse fapaneng tsa taolo ea mochine.

6.Mochini o boetse o na le tlhahlobo ea phoso ea othomathike (ho kenyeletsoa habeli, pampiri ea morero, pampiri le liteko tse ling), sampole e sa khaotseng le mesebetsi e meng, empa khatello ea ho itšeha, ho nepahala ho phahameng ho ngolisoa.

7.Mochini ona o sebelisa moralo oa setempe o otlolohileng le o otlolohileng oa mahlakore a mabeli.Setempe se chesang sa longitudinal le se rapameng se ka etsoa ka nako e le 'ngoe, sa fokotsa haholo sekhahla sa tahlehelo ea foil e chesang.Lihlahisoa tse ling li ka qeta mosebetsi oa pele oa setso o chesang oa ho hatisa habeli.

Hot Tags: foil stamping.mochini oa ho itšeha, lebokose la lebokose.fektheri.Aluminium foil.ho kgabisa ka botebo.bahlahisi, bafani ba thepa, lebokose, lebokose, le itirisang, la masenke, ho nepahala ho phahameng.mokgoaretsi.ketane.die cutter, sekhomaretsi sa foldara, mochini oa ho itšeha le o ntseng o eketseha, mochini o khomarelang oa PE Pet PVC Plastic Film, Mochini oa ho Punching Eyeleting oa Manual, mochini o etsang mekotla, mochini o menang ka har'a Phetoho ea Pampiri.